What is Functional Leak Testing?

What is Functional Leak Testing?

Functional leak testing involves challenging the performance of an assembly against a set of predefined performance criteria. For example, a medical valve may have a torque to turn specification as well as a leak and flow test specification. Functional testers can be used to test valves, turbo chargers, electric motors, thermostats, electronic and mechanical control devices, medical devices, faucets, showers and many other components.

Functional leak testing Equipment

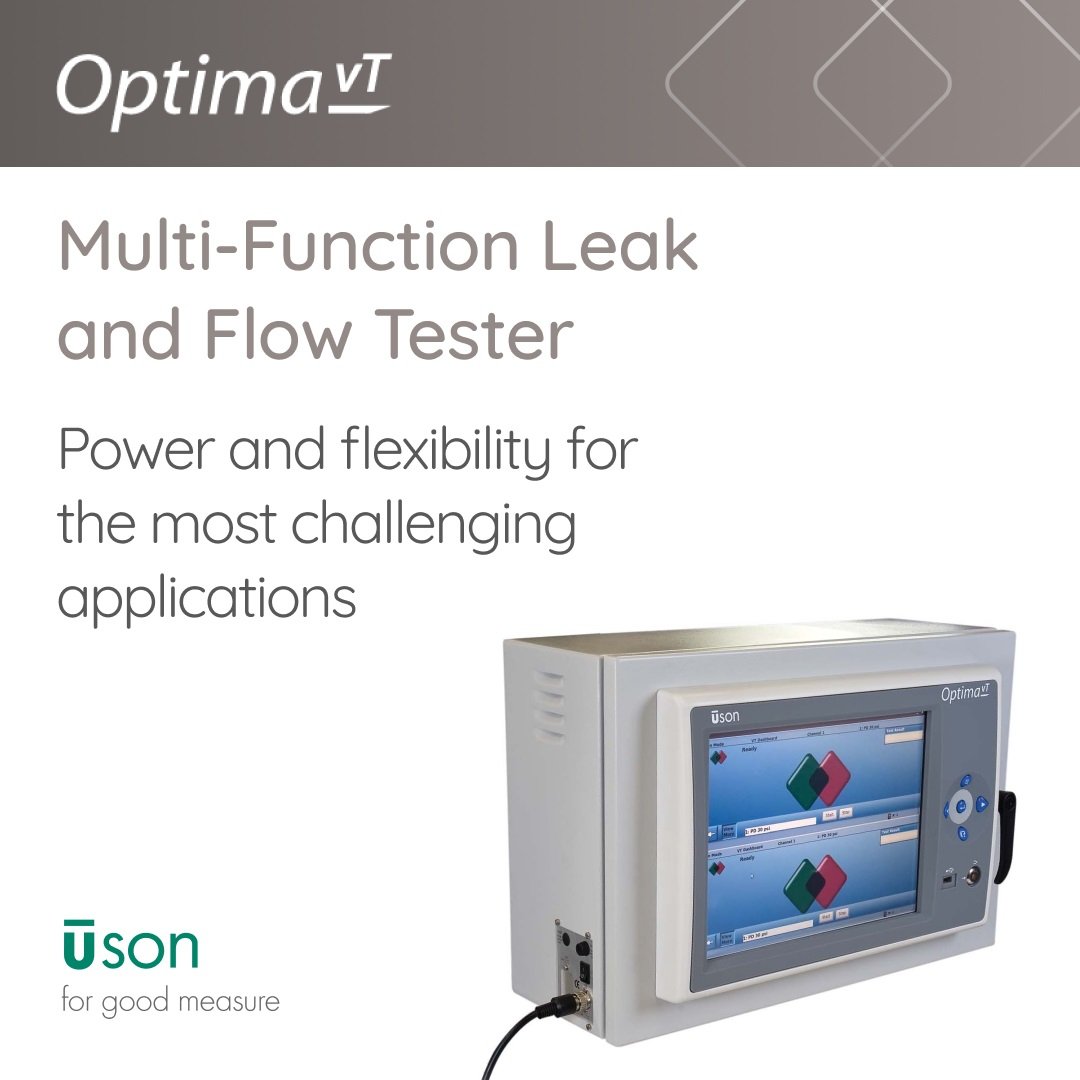

With powerful leak testers like Optima vT and Vector, Uson is able to utilize their formidable capacity to incorporate functional testing where possible. For example a leak test and operational test together with a flow test could be incorporated in a single Vector test station.

Uson’s Innovative Systems (UIS) solution offers custom designed, semi automatic or fully automatic leak testing systems and fixtures for functional leak testing.

Manufacturing and assembly industries around the world depend on functional testers to improve product quality and enhance process uptime.

For functional leak testing requirements, Uson offers the following testers:

The SaaS Sales & Marketing Acronym Bible

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español