Occlusion Leak Test

What is an Occlusion Leak Test?

The Occlusion Leak test is used to test a product’s open passages by trapping pressure inside the product and then measuring an expected pressure loss.

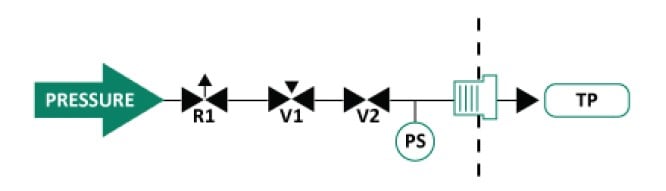

How is an Occlusion Test performed with external seal?

To begin an Occlusion Leak Test with external seal the operator connects a product to the test port and the open end of the product is placed in the sealing (clamping) fixture. The operator then pushes the START switch. Or the start could be activated by automated equipment.

The couple timer provides delay time needed to activate the fixture before starting the test. A coupling valve can be used to supply air to the fixture and hold the seal until the test ends.

At the end of couple time, the pressure decay valve opens and fills the product with air. The tester goes into the stabilize phase only if test pressure is within the pressure error tolerance at the end of the fill phase.

At the end of fill time, valves close trapping air inside the product including the testers internal test circuit. Stabilization time lets the pressurized product settle before the tester starts taking pressure drop readings. For large flow rates stabilization time is not needed and can be set to zero.

At the end of stabilization time, the tester starts looking for a drop in pressure from the stabilized pressure. The tester goes into test phase only if test pressure is within the pressure error tolerance.

During test time, the coupling is released and the test part is opened to atmosphere. The tester compares the pressure drop to the set limits. If the pressure decay (or pressure loss) is greater than the reject minimum at the end of test time, the pass indicator lights up. The fail light turns on if the pressure is less than or equal to the reject minimum. Messages in the status box stay on until the next test.

If the vent parameter is set a time other than zero, the vent valve vents the product to atmosphere. If another test is linked to the occlusion test, the tester goes to the next linked test in the series as long as the product passed all tests.

At the end of all linked tests, the operator (or automated machinery) removes the product and the tester is ready to begin the next test.

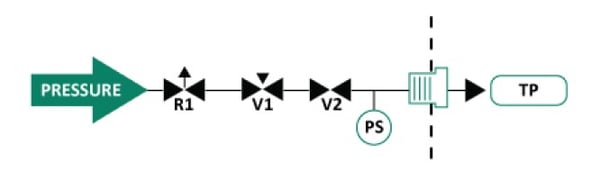

How is an Occlusion Test performed without seal?

To being an Occlusion Leak Test without seal the operator connects a product to the test port and the open end of the product is allowed to flow to atmosphere. Next, the operator pushes the START switch. Alternatively the start can be activated by automated equipment.

The couple timer will not be used for this test. (The couple timer provides delay time needed to activate the fixture before starting the test.) At the start of fill time, the pressure decay valve opens and fills the product with air.

If the part is blocked the test pressure will rise too high during the fill time, above the pressure error limit, and the test will fail. This is a fast test for a relatively large change in the flow rate. At the end of fill time, valves close stopping the flow of air to the product.

Stabilization time will not be used in this test. (For large flow rates stabilization time would allow the pressure to flow out before pressure drop readings can be taken in the test time.) The tester goes into test phase only if test pressure is within the pressure error tolerance by the end of the fill phase. (Again, no stabilize time is needed for large flow rates.)

During test time, the tester compares the pressure drop to the reject minimum. If the pressure decay (or pressure loss) is greater than the reject minimum at the end of test time, the pass indicator lights up. The fail light turns on if the pressure is less than or equal to the reject minimum. Messages in the status box stay on until the next test.

Note: If the fill time check is sufficient for your needs, the test time may be set to 0.1 second and a small decay value entered to allow this portion of the test to always pass.

If the vent parameter is set to a time, the vent valve vents the product to atmosphere. If another test is linked to the occlusion test, the tester goes to the next linked test in the series as long as the product passed all tests.

At the end of all linked tests, the operator (or automated machinery) removes the product and the tester is ready to begin the next test.

Testers Supporting Occlusion Leak Tests

The SaaS Sales & Marketing Acronym Bible

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español

.jpg)