Pressure Decay

Leak Test

What is Pressure Decay Leak Testing?

The Pressure Decay test, also known as gauge decay, absolute pressure, leak drop or delta pressure leak test. This test method measures the drop in pressure on a gauge (transducer) during the leak test. Pressure decay leak testing is used to test products for leaks by trapping pressure inside a product and then measuring pressure loss.

In this test method the component is pressurized with air and the pressure transducer monitors the pressure for negative changes. Any pressure drop indicates a leak. The pressure change from the first measurement to the last measurement made during the test phase of a test is what is important.

The test is very fast, a matter of seconds, and is therefore popular for leak testing in high-volume industries such as automotive components, castings, medical devices and consumer goods.

How is a Pressure Decay Test performed?

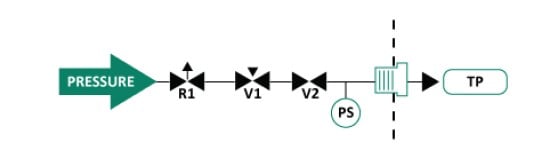

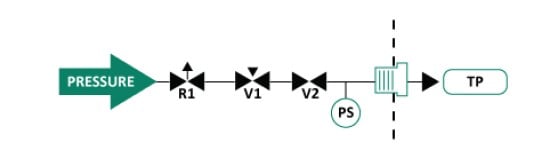

To begin the Pressure Decay leak test, the test part [TP] is attached to the test port. The tester then pressurizes the part with pressure [+P] to the desired test pressure set by the pressure regulator [R1] during the Fill step by opening valves [V1] and [V2].

Upon completion of the Fill step, pressure is trapped inside the part as [V2] closes. After a slight delay, [V1] closes allowing the line between [V1] and [V2] to vent to atmosphere through [V1] allowing any leakage through [V2] to cause the tester to see this leakage and fail all tests. The extra valve allows for a fail-safe configuration.

Trapped pressure inside the test circuit is held through the Stabilize step and then measured by the testers pressure sensor [PS] during the Test step.

If the part exceeds the programmed leak tolerance (pressure drop over time or quantified leak rate), the tester’s display indicates the reason for the test failure and displays the pressure loss or leak rate in user defined units of measure.

Upon completion of the Test step, pressure trapped in the part is vented to atmosphere through [V1] by opening [V2] during the Vent step, and the tester is ready for the next test.

Learn more about Pressure Decay Leak Testing from the video below:

Benefits of Pressure Decay Testing

Pressure decay testing offers several benefits when incorporated into the manufacturing process for leak detection across various industries. Here are the key advantages:

- Early Detection of Leaks: Pressure decay testing allows for the early identification of leaks in manufactured products. Detecting and addressing issues at this stage prevents defective items from progressing further in the production process.

- Quality Assurance: By implementing pressure decay testing, manufacturers can ensure the quality of their products. This method helps maintain consistent quality standards, reducing the likelihood of faulty or substandard items reaching the market.

- Cost Savings: Detecting and addressing leaks during the manufacturing process is more cost-effective than discovering issues after products have been shipped or installed. Early intervention minimizes the need for costly recalls, repairs, or replacements.

- Increased Efficiency: Pressure decay testing is a fast and automated process. Its efficiency makes it suitable for high-volume production, allowing manufacturers to conduct thorough leak tests without causing delays in the assembly line.

- Non-Destructive Testing: Pressure decay testing is a non-destructive method, meaning it can identify leaks without damaging the product. This is crucial for items that need to maintain their structural integrity and functionality throughout their lifecycle.

- Adaptability to Various Products: This testing method is versatile and can be applied to a wide range of products across different industries, including automotive components, electronics, medical devices, and consumer goods.

- Process Integration: Pressure decay testing can be integrated seamlessly into existing manufacturing processes. It can be automated and synchronized with other production steps, ensuring a smooth workflow.

In conclusion, pressure decay testing is a valuable tool for manufacturers, contributing to improved product quality, cost savings, and overall efficiency in the production process. Its versatility and non-destructive nature make it an effective method for detecting leaks across a wide range of manufactured goods.

Testers Supporting Pressure Decay Tests

The SaaS Sales & Marketing Acronym Bible

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español

.jpg)