What is Leak Testing?

Modern Leak Test Methods

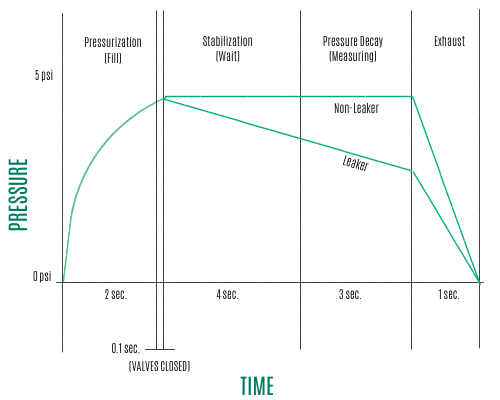

Leak testing is the process of checking a product for leaks (a defect) and may be achieved using various test methods. Modern leak testing uses air pressure, electronics, and pneumatics components to perform pressure testing. Electronic pressure testing involves filling a test with air pressure, allowing it to stabilize, and then checking for leaks.

These three major steps of modern leak testing are called:

- Fill

- Stabilize

- Leak

The computer or electronics control the timing of each step and reads the air pressure of the test part. The pneumatic components control where the air pressure goes and convert the test part air pressure to an electrical signal.

The pneumatic component that converts air pressure to an electrical signal is called a Pressure Transducer. During the Leak step, the computer reads the pressure transducer many times to create a graph of air pressure values over time. After the Leak step, the computer compares the air pressure values to the values of a known non-leaking part. If the values are comparable, the tested part is good.

What Types of Leak Test Methods can be Performed?

Below is a list of the most common test methods including links to detailed information about the test:

Uson Leak Testing Equipment

Uson manufactures leak testing equipment for a variety of applications including medical, automotive, industrial, and packaging. We specialize in partnering with manufacturers to design product testing systems that optimize their manufacturing processes. Our team of experts are ready to assist you with your next manufacturing project.

The SaaS Sales & Marketing Acronym Bible

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español