Large Volume Pressure Decay Test with Fast-Fill

The fast-fill option allows large products to reach test pressure much faster than would be possible using the standard test pressure for inflation.

High-pressure air is frequently required to operate external clamping devices used to seal the product under test. In other situations, high pressure air is used to inflate the product itself. To supply these high-test pressures (typically from 150 to 500 psig), some firms bring in bottles of compressed gas, or install high-pressure motor-driven air compressors. Motor-driven compressors have a large energy demand, are noisy, can be fire hazards, and require maintenance to keep them clean and working. Gas cylinders are expensive to rent and can be dangerous to store in production settings.

Uson can supply a custom-matched pressure booster operated by normal house air. An air input of 80 psig can be boosted to pressures up to 500 psig. A Uson pressure booster has these advantages over motor driven compressors and gas bottles:

Quiet: No loud motors and pistons

Safe: No risk in overheating or explosion.

Clean: No oil to contaminate air.

Small: No need for large production space.

Besides these advantages, a Uson pressure booster costs much less than renting gas bottles or buying a clean, high-pressure, motor-driven compressor.

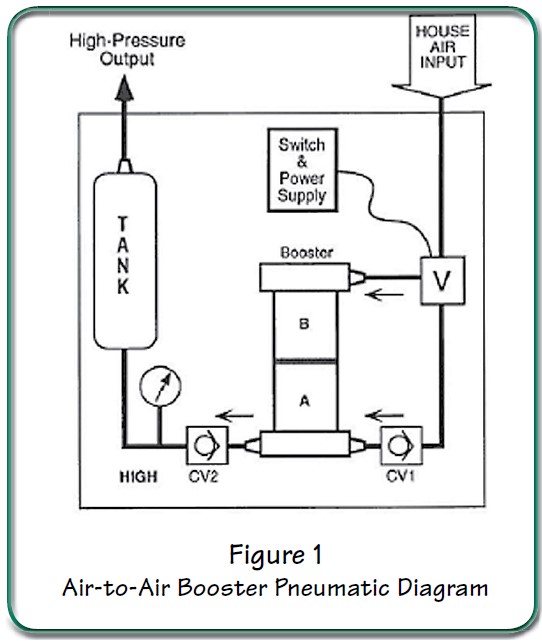

The pressure booster works like this:

The packaging of multiple states (pistons) exerting force on a common shaft produces an air output with a potential much greater than the air input. Think of it as an air multiplier: with each stroke of the piston, the same multiplied air is created. Of course, the piston must activate a number of times to create the required volume of air; the higher the output pressure, the more times the piston must activate.

Output force is a function of the cylinder multiplied by the total effective piston area (one piston times the number of stages). The output force is therefore two, three, or four times that of a conventional single-piston cylinder.

Uson can design a pressure booster specifically for your requirements. The booster is contained in a metal enclosure and there is no risk of moving parts or electrical exposure to the operator. All the customer needs to do is supply clean, dry air; generally, the same air delivered to the tester.

By selecting the proper combination of bore size, stroke, power factor and regulating input pressure, the exact output pressure and required volume can be achieved and maintained. For testing small parts or operating small clamping devices, a small pressure accumulator is adequate. For larger products and clamping devices, a larger pressure accumulator can be used.

Consider using a pressure booster when an air pressure above normal house air is needed to operate clamping devices or for high test pressures.

A pressure booster can be applied to manual or automated operations.

Uson supplies a complete ready-to-operate system. The customer need only supply AC power and clean, dry house air.

Please contact Uson for assistance in selecting the optimum air-to-air booster for your application.

The fast-fill option allows large products to reach test pressure much faster than would be possible using the standard test pressure for inflation.

The Sprint iQ bidirectional check valve tester is equipped with a precision flow control and two pressure sensors.

The Sprint iQ check valve tester is equipped with a flow control and an additional transducer called a downstream sensor..

Industries