Pressure Booster Accessory

Uson pressure booster offers a safe, quiet and cost-effective alternative to renting gas bottles or buying a clean, high-pressure, motor-driven...

Products such as one-way valves are often built to open at a certain pressure. Product and test engineers need to know at what pressure the valve starts to open (cracking pressure) and if the valve body breaks.

Typical leak testers cannot determine the cracking pressure because they use merely one pressure sensor upstream from the product being tested. The upstream sensor is constantly supplied with air, so sensing the downstream pressure change is next to impossible. Such typical leak testers also cannot reverse the pressure going to the two sides of the product to perform a bidirectional leak test.

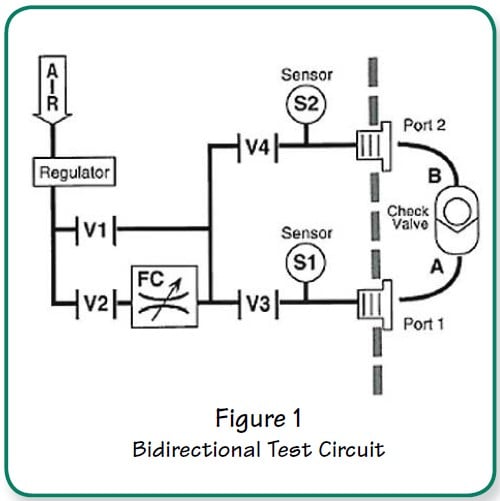

The Sprint iQ bidirectional check valve tester is equipped with a precision flow control and two pressure sensors. All components are contained in Sprint’s small enclosure. The downstream sensor detects precisely when the product opens and starts to fl ow air. This tells test engineers exactly what pressure the device is being tested starts to crack open.

The Sprint iQ bidirectional check valve tester can also reverse the air fl ow to determine how well the valve holds pressure on the B-side of the product. This standard option is another example of why Sprint iQ is much more flexible than any other leak tester you can buy.

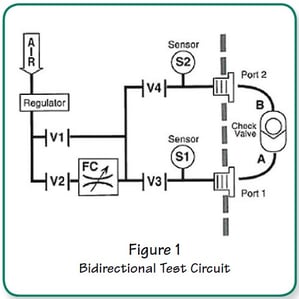

Pressure slowly ramps up through the flow control and pressurizes the upstream side of the product. Curve [A]. During the gradual pressure increase, the pressure measured on the downstream side of the product remains near zero. Curve [B].

The leak tester’s downstream sensor looks for the slightest pressure above zero at the B side of the product. When the pressure exceeds the preset pressure limit (dashed line), the EVENT is detected and Sprint iQ stops the test. If the downstream sensor does not detect an event (pressure exceeding the pressure limit within the established test time), the program times out and Sprint iQ shows NO CRACK in the status box on the LCD display.

The check valve tester is valuable when testing duck-bill valves, check valves, pinch valves or devices that open slowly under applied pressure.

You can use the Sprint iQ bidirectional check valve tester to check for both cracking pressure and for body leaks in the valve body.

This machine can be used to perform normal pressure decay tests on either test port. Bypass valve [V1] is used as a fast-fill valve in pressure decay testing.

A variation of the bidirectional configuration tests product in one direction. See the separate Uson Application Note describing the downstream sensor option.

Uson pressure booster offers a safe, quiet and cost-effective alternative to renting gas bottles or buying a clean, high-pressure, motor-driven...

Test the integrity of the cylinder head water jacket for porosity, while simultaneously testing each oil drain-back hole for casting blockage.

The fast-fill option allows large products to reach test pressure much faster than would be possible using the standard test pressure for inflation.

Industries