Leak Tester Sustainability

Leak tester sustainability is discussed in Uson's latest leak testing blog. Purchasing decisions need to be future minded.

Determining the best leak tester is not a straightforward task, as what may be best for one application may not be the best for another. While partnering with experts can make the process easier, there are ways to make an informed decision and choose the leak tester that suits your specific needs. In this blog post, we will explore five factors that can help you identify the perfect leak tester for your requirements.

Application Details

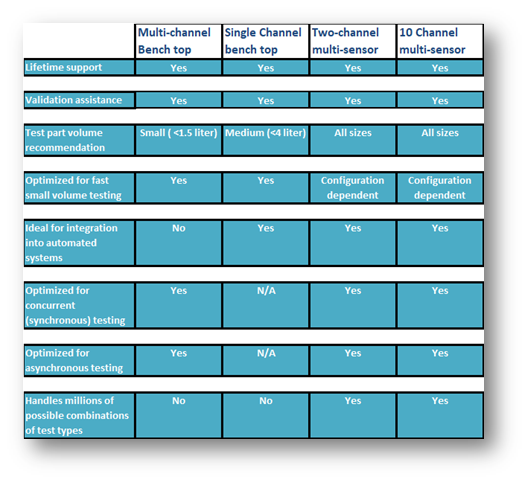

Before engaging in a conversation with a leak testing specialist, it is crucial to come prepared with a detailed understanding of your application. Consider Figure 1, which provides an overview of how different classes of leak testers align with specific requirements.

After gathering all the necessary information about your application, you are now ready to move forward and explore the various options for leak testers. Here are five key factors that will guide you in finding the best leak measurement equipment for your specific needs:

When consulting with a leak test specialist, it is essential to prioritize detailed visual inspection and, in some cases, dissection of the assembly. Face-to-face discussions, or video conferencing, are always a superior option compared to phone conversations. These video consultations allow for precise recommendations regarding seals or fixturing in automated machinery that match the physical characteristics of the product, such as its geometry and flexibility, ultimately improving testing efficiencies. This is especially important when dealing with patent-pending medical devices that cannot leave the manufacturer's facility. Videoconferencing eliminates this obstacle and enables experts to provide valuable insights and recommendations.

Factor #3. Testing Sequence

Make sure that the discussions include a detailed analyses to determine if parts of components can be leak tested simultaneously or if the sequence of tests required makes asynchronous multi-channel leak testing a better match. This is not simply a matter of looking at lower costs, though that is one inevitable byproduct when getting into this level of detail. It is also a matter of test accuracies afforded by sensors that are tuned to different pressures as well as the cycle time for tests with particular sensors. Multi-channel and multi-sensor leak testers are the types where the most recent innovations have occurred.

For example, consider an engine block. Chambers for water used to cool the engine are separate from oil used to lubricate the internal engine components and operate at different pressures. In addition, testing a part with multiple internal chambers separated by shared wall requires not only testing each chamber, but measuring leaks present in the shared wall. This scenario requires sequential testing at different pressures to measure potential leaks in chamber and shared wall(s) of the chamber(s). Note that the up-front cost of any leak tester is different from the actual testing costs. Cycle times factor in and, in turn, relate back to the sensitivity and pressures to which the sensors are being used and tuned. Testing costs per channel and testing costs per sensor are factors that create significant considerations in the purchasing decision.

Factor #4. Features and Options

The range of options available for leak testers is extensive, encompassing factors such as I/O sophistication and the programmability of test steps. For those who prioritize flexibility, leak testers have been specifically designed to meet this requirement. Additionally, some leak testing equipment offers a wide array of data communication options. While these factors are always important for any system, they become crucial when seeking a leak tester manufacturer to provide a comprehensive turnkey leak test solution. It is essential to carefully consider and plan these aspects in detail to ensure the best possible outcome.

Factor #5. Configurability

The necessary configurability of the leak tester needs to be identified. Today’s technology improvements allow engineers to pick leak testers with totally customizable pneumatics, test methods, data communications, and storage. For example, with a system capable of performing more than a dozen types of NDT tests in any order, the number of permutations reaches into the millions; it is easy to see how flexibility needs to be a focal point. Additionally, configurability enables the engineer to not only have the best leak test technology for the application at hand, but also for the next device that is only on the drawing board.

Perhaps the biggest mistake manufacturers make is when an antiquated leak tester that was built with one pressure and sensor range in mind for an earlier generation device is used for a new application. While it will work in some fashion, it is certainly not optimal. Typically, the regulators and flow sensor ranges are off and the tester “limps” to the finish line during every test cycle. Often, it will only take 48 hours to get a no-cost detailed application analysis to determine if a leak tester is suitable for a specific task.

By considering these five factors and collaborating with leak testing specialists like Uson, you will be well-equipped to find the best equipment for your needs, putting you on the path to success.

If you have questions or need guidance, Uson is here to help. We've helped thousands of customers work through the five factors discussed in this article and set them on the path to success. We can help you too. Contact us today!

Leak tester sustainability is discussed in Uson's latest leak testing blog. Purchasing decisions need to be future minded.

Uson has identified air leak testing as a viable option to helium leak testing in some EV Battery leak testing applications.

Uson Innovative Systems provides turn-key medical device leak testing automation & validation systems that lower costs & increase throughput.

Industries