Like its predecessors, the SprintmD tester is capable of successfully tackling complex leak testing challenges. In this article I am going to take a deep dive into performing a check valve test with the Sprint mD leak tester, specifically how to approach testing the cracking or opening pressure of valves. The pressure at which the valve opens is a crucial performance factor and the SprintmD manages this application with ease. A simple check valve test can trip up most most leak testers. Here’s why:

The majority of pressure decay leak testers have one pressure sensor located upstream of the product being tested. This sensor is constantly supplied with air making detecting a downstream pressure change extremely difficult.

Two Pressure Sensors Are Better Than One

The SprintmD can be configured with highly precise flow control and two pressure sensors inside its already compact enclosure. The second pressure sensor or mass flow meter is positioned downstream of the valve and detects precisely when the valve opens and starts to disperse air. The change in pressure on the downstream side will tell the product engineer exactly how the valve will behave in its real, intended application.

The downstream sensor option can be applied to many SprintmD leak testers.

How The Check Valve Test Works

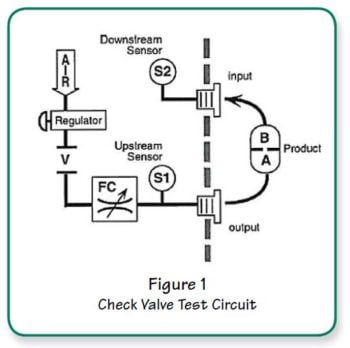

The SprintmD check valve tester works like this (Figure 1):

- Product is attached to Sprint mD’s output and input ports either manually or by an automated mechanism.

- The test is initiated by pressing the tester’s start button or by remote signal.

- Sprint mD slowly pressurizes the A side of the product through valve [V] and the flow control [FC].Pressure to the A side of the product is measured by the upstream sensor [S1].

- The downstream sensor {S2} measures either a pressure or flow from the B side of the product.

- Once the pressure or flow monitored at [S2] reaches the preset threshold, the test is stopped and the results displayed. Sprint mD’s display shows the pressure applied to the A side of the product.

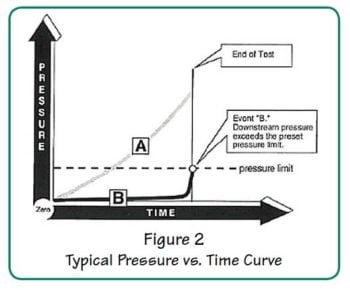

Pressure / Time Sequence

- Pressure slowly ramps up through the flow control and pressurizes the upstream side of the product. Curve [A].

- During the gradual pressure increase, the pressure measured on the downstream side of the product remains near zero. Curve [B].

- Sprint mD’s downstream sensor looks for the slightest pressure above zero at the B-side of the product.

- When the pressure exceeds the preset pressure limit (dashed line), the EVENT is detected and the tester stops the test.

If the downstream sensor does not detect an event (pressure exceeding the pressure limit within the established test time), the program times out and SprintmD returns a FAIL result.

Applications

The check valve tester is valuable when testing duck-bill valves, check valves, pinch valves or devices that open slowly under applied pressure.

A downstream sensor is especially valuable for testing products that merely weep open or flow just a small amount when fully open.

The downstream configuration can also be used to leak test products that have two chambers not intended to have a passage between the two sides.

SprintmD can be used to perform normal pressure decay tests on either test port by incorporating a bypass valve that is used fast-fill valve in pressure decay testing.

Sprint mD Features

- More sensitive than typical leak testers

- Senses downstream pressure or mass flow

- Adjustable precision flow control is built i

- All components are in one small enclosure

- Small footprint of 8.5 by 15 inches

- Perfect for bench or automation

- High pressure resolution

- Easy to program and re-calibrate

For more information or to schedule a demo of the SprintmD or any of our leak testers contact us directly to speak to our experts, or reach out to your local Uson representative.