The Problem

When conducting multiple tests using different test pressures, operators face the problem of constantly adjusting manual air pressure regulators. This is not only time consuming, it elevates the skill level required and increases the odds of human error when leak testing.

A cracking pressure test (often used for valve testing) frequently requires multiple ramp rates. Operators must adjust manual flow controls to various ramp rates needed for the different tests.

Manual pressure controls in leak testing are subject to operator error when setting test pressure. A common cause of erroneous results comes from accidentally bumping the regulator control is a possibility when using the equipment in production settings.

The Solution

Many of Uson’s leak testers can be supplied with an electronic regulator, a sophisticated electro-pneumatic device programmed by setup personnel to supply the exact test pressures.

The programmable regulator can also be set to slowly increase pressure over time. This provides a variety of consistent ramp rates often used in crack, burst and valve leak testing.

Because the regulator is programmed, it can supply different test pressures or ramp rates for each of the tester’s stored programs and no operator adjustment is needed.

The programmable regulator works like this:

The leak tester is set to program mode

In the program setup screen, setup personnel enter test pressure values using the instrument’s normal programming methods

Different test pressures can be entered for each of the tester’s stored programs

Multiple test pressures can be entered, depending on the tester specifications. When in run mode, the electronic pressure regulator automatically goes to the set test pressure to provide the desired pressure or ramp rate for one or multiple products (Figure 1)

Test Pressure

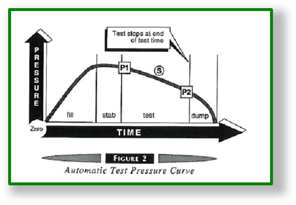

Test Pressure is the pressure to which leak tester pressurizes the product before beginning to look for a pressure drop over time.

The programmable pressure regulator automatically supplies the necessary pressure to achieve the desired test pressure. (Figure 2)

Ramp Rate

Used in crack, creep and burst testing, Ramp Rate is the increase in pressure over time. The electronic regulator controls the ramping pressure.

To program the ramp rate, a rate in pressure units per second is entered.

For example, if 10 psi/s is entered, the pressure goes up 10 pounds per square inch every second.

QualitekmR(pictured above) is just one Uson tester supporting an electronic regulator option.

Applications

Consider using the programmable pressure regulator option in any application where multiple test pressures or multiple ramp rates are needed. The programmable pressure regulator can be useful in bench or automated systems. One tester using the programmable pressure regulator can be used in place of multiple machines set at different fixed pressures.

Use in critical applications where it is important to prevent users from changing the machine setup.

Please contact Uson to see how the programmable pressure regulator can work in your next testing application.

Benefits

- Multiple test pressures run automatically

- Multiple ramp rates run automatically

- Eliminates manual pressure adjustment

- Eliminates manual flow control adjustment.

- Setup personnel can lock out user adjustments

- Perfect for bench or automation

- Contained in leak tester’s enclosure.

- Easy setup with normal programming.

- Replaces machines with fixed test parameter

For more information about this subject click here to contact us via email or call us at 281-671-2000.